In modern manufacturing environments such as food, feed & beverage, pharmaceuticals, and chemicals, efficiency is crucial. Two systems that play a significant role in this efficiency are the Manufacturing Execution System (MES) and the Warehouse Management System (WMS). While both systems focus on different parts of the production process, they greatly enhance each other when well integrated. In this article, we’ll explore what this collaboration looks like and the benefits it brings. Remember: the power of MES-WMS integration in manufacturing is key.

What is an MES and a WMS?

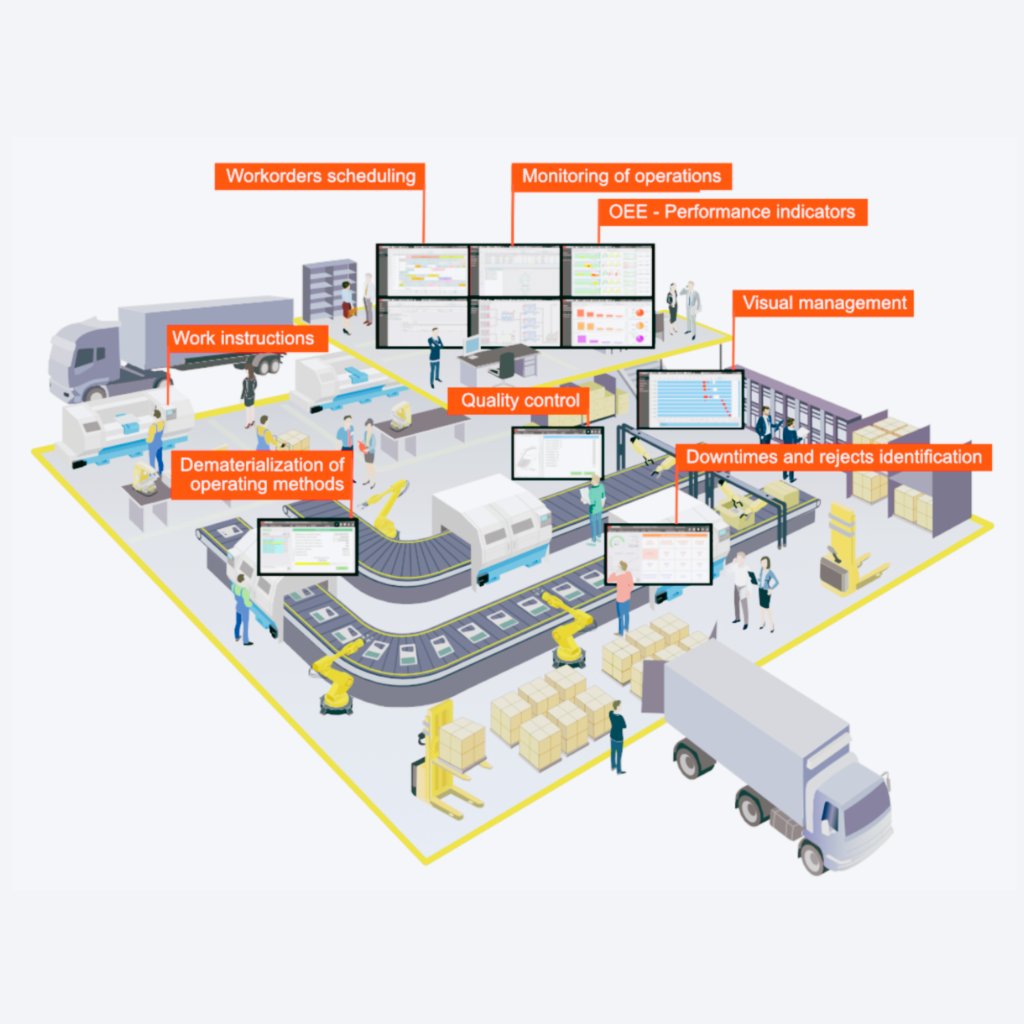

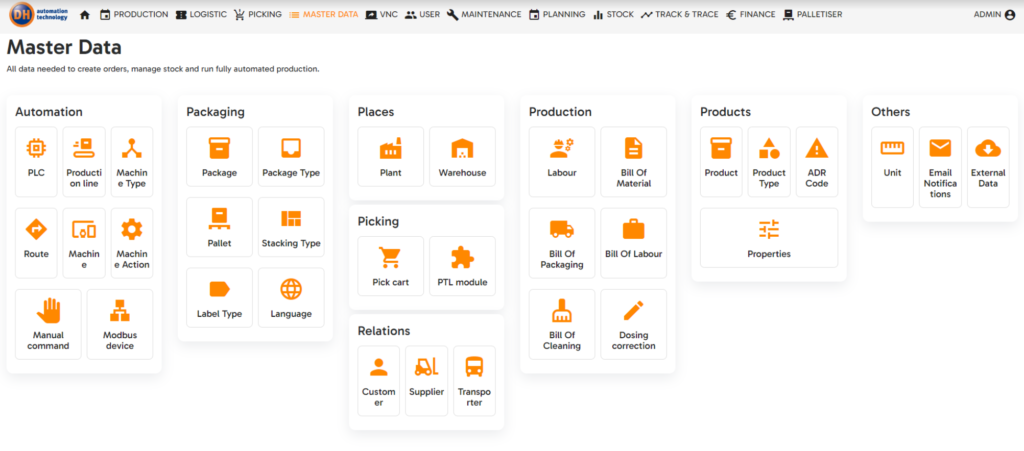

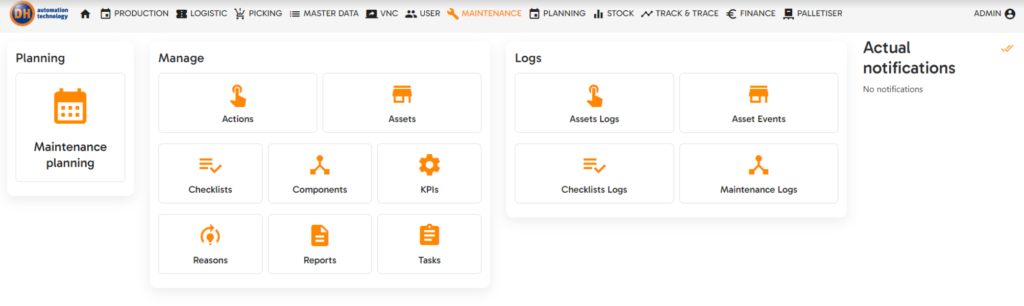

An MES is a system that manages and optimizes production processes in real-time. It connects the shop floor with the ERP (Enterprise Resource Planning) system, making processes such as production planning, quality control, and inventory management visible and manageable.

A WMS focuses on the storage and movement of goods within the warehouse. It ensures that raw materials and finished products are efficiently stored, picked, and shipped. It provides real-time insight into warehouse inventories and ensures a streamlined logistics flow.

How MES and WMS Complement Each Other

- Real-Time Inventory Management

In a manufacturing environment, it’s essential that the right raw materials are available just in time for production. The MES signals material needs on the shop floor. The WMS responds by releasing the required raw materials from the warehouse and transporting them to the production line. This synergy prevents production interruptions and minimizes wait times. - Quality Control and Traceability

Especially in regulated industries like pharmaceuticals and food production, full traceability of raw materials and finished products is mandatory. The MES records which raw materials are used and in which production batches they end up. The WMS complements this data by tracking the origins of raw materials and where finished products are stored or shipped after production. This creates a complete digital chain from source to finished product. - Production Balance and Efficiency

A well-integrated MES and WMS prevent disruptions in the balance between production and storage. The MES aligns production speed with the availability of raw materials and warehouse capacity. The WMS monitors inventory levels and ensures that finished products are distributed from the warehouse on time, preventing unnecessary storage buildup. This is particularly relevant in industries with short shelf lives, such as food and beverage. - Reduction of Errors and Waste

Automatic communication between the MES and WMS eliminates human errors. For example, when the MES indicates which raw materials are needed via production schedules, the WMS automatically generates the correct picking orders and movements. This prevents wrong materials and overproduction, leading to less waste and higher cost efficiency. - Quick Response to Demand Changes

In dynamic markets like food and pharmaceuticals, demand patterns can change rapidly. When the ERP detects a change in demand, the MES can immediately adjust production orders and inform the WMS of new storage and distribution needs. This keeps the supply chain operating smoothly and flexibly.

Concrete Benefits of MES-WMS Integration

- Shorter Lead Times: Raw materials and products move seamlessly between the warehouse and production without delay.

- Increased Customer Satisfaction: Accurate inventory levels and timely delivery help meet customer expectations.

- Compliance and Audits: Seamless traceability of materials and products simplifies audits and meets regulatory requirements.

- Cost Efficiency: Automation and precise alignment between production and warehouse prevent waste and unnecessary inventory.

Conclusion

In the semi-process industry, the collaboration between an MES and a WMS is a powerful combination that optimizes production and logistics processes. Through real-time data exchange, these systems ensure smooth production, maintain quality, and optimize inventory management. This integration provides companies with the flexibility and efficiency needed to remain competitive in markets with ever-increasing demands.

In short, linking MES and WMS is not just a smart investment; it’s an essential step toward a more optimized, sustainable, and customer-centric manufacturing environment.

Want to learn more about how your organization can benefit from MES-WMS integration? Contact us for a no-obligation consultation or advice!

Author is Harry Luijk – Manufacturing, Logistics & Supply Chain Professional – CCO at DH Automation Technology BV – Partner at Merlyn Consult.